Large Scale CNC

Firstly we fabricated a coaster to learn how to operate and configure the CNC.

I have chosen to fabricate a Hexagonal shaped coaster.

It has to be program to have 2 steps, with first a profile cut on the external hexagon, and a pocketing operation inside to hold the cup.

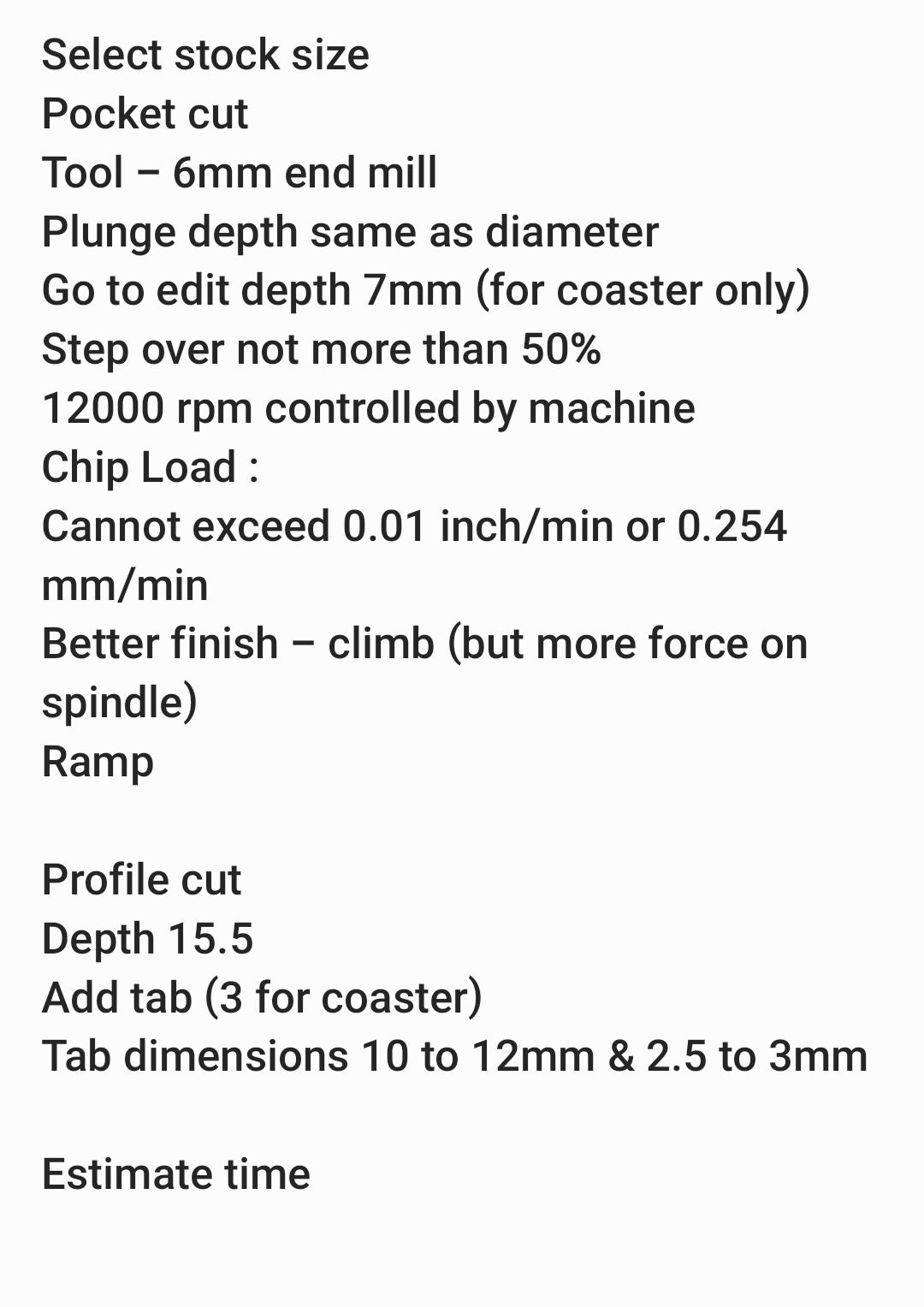

Cutting process:

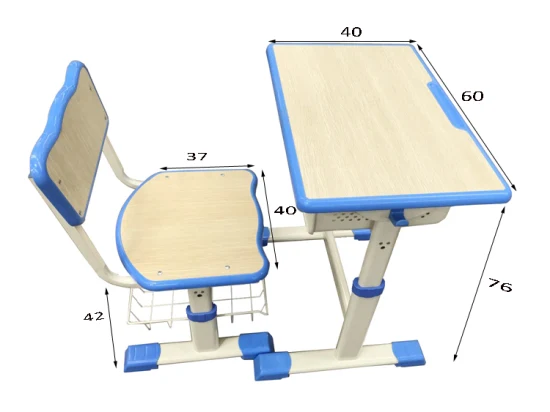

Next we designed and fabricated a flat packed furniture. The furniture I have opted to design is a convertable table and chair.

A dogbone addon is installed onto Fusion 360, where it could be applied on edges with joining parts, to allow fitting of the pieces together, getting rid of the tool nose radius issue.

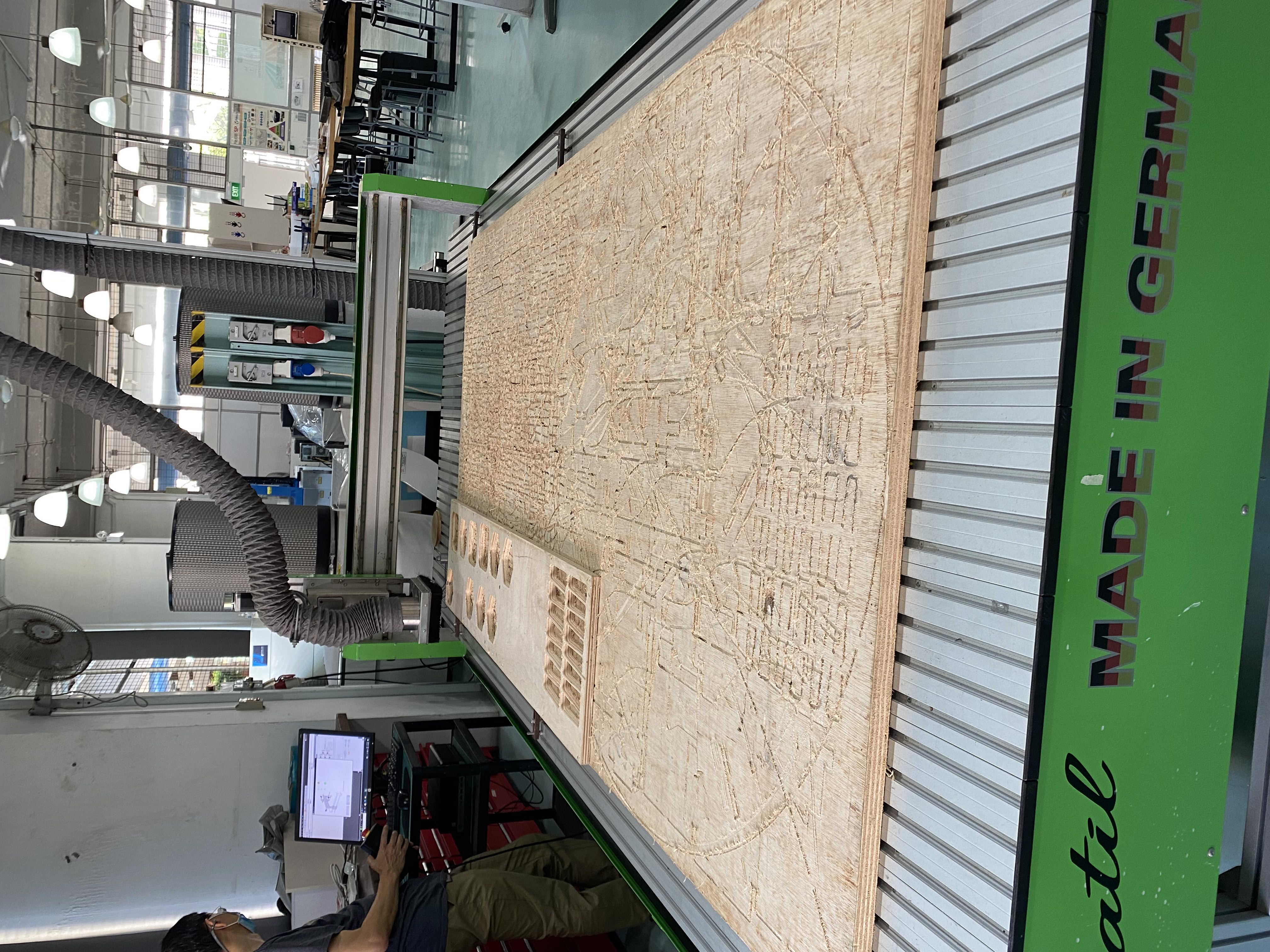

To fabricate the flat pack, we aligned a piece of 18mm plywood,

and then screw in to make sure the plywood is flat and not warpped so some parts are higher that the others.

We then loaded in the drawing files and selected the operations for each line.

For this flat packed furniture, all the operation were Profile cuts.

Cutting process:

Final furniture: